Here is the upbeat Polyworld in 1985 winter, Click HERE to read the entire contents.

Polychrome Corporation, a brainchild of Mr. Halpern, is now a major part of Kodak Co. and continues to live on. But the small company spirit died on Jan 1. 1998 when the company became a part of DIC-Kodak joint venture. This blog is dedicated to the memory of those who proudly call themselves "Polychromer". ..... Ken Shimazu shimazukenichi@gmail.com

Wednesday, January 30, 2013

Monday, January 28, 2013

email from Bill Rodriguez Polychrome Alumni '59-'60

Greetings,

I just looked over the archive of Polychrome Corp. I worked in the lab with Simon Chu, Ibert Mellon, Al Taudien and Jerry O'Connor after I graduated from CCNY in 1959 (B.S. Chemistry). I remember many of the early names; Bob Gumbinner, Ray Lauzon, etc. Mr. Halpern hired me right out of college but I only worked there for about a year. I was encouraged by Simon and Jerry not to be drafted and to go into the service as an officer. I took their advice and signed up for the Naval Aviation Officer Candidate and received my commission in December 1960. I became a Naval Flight Officer and attained the rank of Captain (O-6) and retired from active duty in 1987. I live now in Atlantic Beach, Florida. I sort of followed Polychrome for many years after the stock went public and I always regretted not buying it.

I enjoyed seeing all the old pictures of my colleagues and the building on 2 Ashburton. Times have changed but I always will be thankful for the advice I received from Simon and Jerry. The Navy was a wonderful career for me.

Best wishes,

Bill Rodriguez

and my immediate response

Hello Bill Thank you very much for your note. I just had lunch with Simon Chu this week and the name of Jerry O'Connor surfaced as a good chemist who chose more promising career of sales. Ray Lauzon and I worked closely when he ran Fernwood paper coating factory before his untimely death by traffic accidents. I spoke to Bob Gumbinner the other day. He is 94 and is doing well in retirement home in Virginia. Thank you again for writing to me. I thought this archive reached only to those in my close circle. I am delighted the blog is reaching wider audience. May I post your mail on the blog? Perhaps this would encourage more to surface!? Thanks Ken

and Bill writes again

Hi Ken,

Thanks for your reply. It was a long-shot email that worked out just great. How is Simon doing? Please say hello for me and let him know how grateful I have been for his advice. Also say hello to Bob but I am sure he doesn't remember me. I didn't know Ray too well but I am sorry to hear about his death. Jerry always said that sales was where the action was.

I know a guy in Europe named Gerald D'Avignon who works for Sun Chemical. Somehow or other we got around to talking about Polychrome. Today I thought about him, he's the son of my gal Helene's cousin who lives in Belgium, and checked Google. One thing led to another and I wound up on your blog, which I read for about two hours looking for old names and faces. It was a very interesting and informative history of the company. Polychrome was a big step up for me from the streets of the Inwood section of Manhattan.

If you are interested in classical music please check out my website dedicated to my great-great-grandfather; www.julianfontana.com .

My best wishes to you and also my thanks for your blog. I know it takes a lot of work and dedication. Please feel free to post my letter.

Bill

(Thanks Bill for writing!)

Saturday, January 26, 2013

RRD a Pied Piper of digital era

RR Donnelley & Sons, the world largest printer then, played a pivotal role in the dawn of digital platemaking. In late 1980 after the successful introduction of our Laser Scan OPC-B at the Wall Street Journal, Don Reeves, an exec. VP and John Michaelis, a Technical Manager at RRD came to Polychrome to describe their vision of future darkroom-less platemaking. Their vision was sending electronically composed page directly to a digital platemaker placed next to press so that there would be no darkroom operation involved. In order to achieve their vision they would need a plate capable of being exposed digitally, they said. Unfortunately the OPC-B did not fit the bill as the resolution requirement exceeded OPC's capability. They then toured around the world promoting their concept to encourage hardware companies to develop suitable equipment and plate manufacturers to develop suitable plates. On their encouragement numbers of hardware companies such as Linotype Hell, Misomex, Gerber, Creo and others started to develop laser platemaker. At Ipex in 1993, these companies showed freshly designed platemakers. Numbers of plate manufacturers came up with plate designed for such laser platemakers. Polychrome's answer was to use CTX and working closely with platesetter manufacturers we installed CTX in numbers of customer sites. In early days the competitions were mainly from Kalle's photopolyer plate and Howthon's Silverlith plate. Due to its combination of high sensitivity and good plate performance, the CTX became THE plate for many laser platemakers. In fact in 1995 Drupa, experts said to go to Polychrome and see all the digital system in operation. We had Gerber, Linotype Hell and Creo machines running with CTX. No other companies offered a plate with such a wide latitude in exposure and good on press performance.

However, the preheat thermal plate offered by Kodak on Creo equipment received wide attention at the show as it was the system RR Donnelley promoted from the beginning forming a partnership with Creo. Although we did not know then, Creo had financial support by Kodak then. In early 1996 RRD told us they would like us to develop Kodak like preheating thermal plates as they did not like to depend on one supplier for their plate use. We formed a task force and hoped we could have CTX-like company wide participation to the project. But it was Dr. My T Nguyen who quickly came up with an alternative approach to such plate and with a record breaking speed pilot coated, production tested, field tested and then sold to occupy 20% of market share within one year of introduction and 2 years from inception (more on this in separate upload later). We often say that the product development should not be done by technology push but by the market-pull. If ever there is a need for a good example, this must be the one. RRD the customer came up with a vision, encouraged everyone to accept their vision and the entire industry followed their lead to the new digital world.

However, the preheat thermal plate offered by Kodak on Creo equipment received wide attention at the show as it was the system RR Donnelley promoted from the beginning forming a partnership with Creo. Although we did not know then, Creo had financial support by Kodak then. In early 1996 RRD told us they would like us to develop Kodak like preheating thermal plates as they did not like to depend on one supplier for their plate use. We formed a task force and hoped we could have CTX-like company wide participation to the project. But it was Dr. My T Nguyen who quickly came up with an alternative approach to such plate and with a record breaking speed pilot coated, production tested, field tested and then sold to occupy 20% of market share within one year of introduction and 2 years from inception (more on this in separate upload later). We often say that the product development should not be done by technology push but by the market-pull. If ever there is a need for a good example, this must be the one. RRD the customer came up with a vision, encouraged everyone to accept their vision and the entire industry followed their lead to the new digital world.

Sunday, January 20, 2013

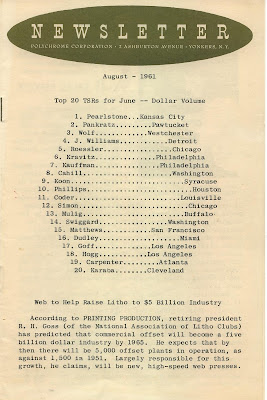

1961 Newsletter .... so far the oldest document found

These are two newsletters by sales department in 1961. I recognize some old names like Pankrats and Wolf. How about you? On the second page there is a picture of Mrs. Margaret McGill using the Addressograph machine!. And Burt Burro joined Newark office this year! See HERE

Friday, January 18, 2013

Competition, Color Proofing and Chrome Guide

In those old days ('60-70), we at R& D considered 3M or Enco as our major competition. On the other hand our sales department friends always reminded us that the real competitions are not these producing products but the local dealers handling them. We were basically direct sales organization selling only Polychrome produchets. Local dealers tended to carry more than one line of products so that they did not bad mouth the product or the producer of products they carry. Since they invariably did not carry Polychrome products and often felt threatened by our aggressive sales force and the pricing, they were quick to point out our deficiencies. I was shown at one of the customer visits in New York how well 3M was doing with their Colorkey color proofing film product and we had no product to compete with. Enco was also starting to experiment with film overlay color proofing system. So I was determined to come up with an alternative, My objective was to use the same pigment used in printing ink to simulate actual printed matters. Unfortunately I did not have enough knowledge of pigment dispersion handling and therefore had difficult time coming up with a product. I was able to demonstrate an overlay color proofing system using dyes but did not consider it to be a viable product. It was Simon Chu who said why not test it in the market place, perhaps there are market for it and thus the "Chrome Guide" was born. By then in addition to 3M Colorkey, Enco was promoting ColorGuide (also with dyes) so this made the third system in the market and Polychrome direct sales force had something to talk about regarding off press colorproofing. This product required delicate handling of thin polyester film, dust free coating area and good cosmetic coating appearance. Unfortunately we did not have coating machine to meet such requirement so that initially we approached K&E coating facility to toll coat the product. As the product expanded we found a requirement for various "flat" colors and the toll coating of numerous colors and sizes became unmanageable. Since the off press color film was limited essentially to 20x24 inch size, we have converted a pilot coater to produce Chrome Guide internally in Yonkers R&D and the production there lasted several years. I may have spoken too quickly at one of the management meeting to review Chrome Guide to kill the project. I was concerned that the dry peel apart overlay system announced by Du Pont will kill any wet chemistry system. I was too naive to think a new and good technology will kill the old technology quickly. It did not and their proofing system died in relatively short time. In addition, I may have been tired of daily production, quality control, trouble shooting, etc. pressure; I was eager to move on to newer R&D challenge. If I knew what I know today that the Chrome Guide had a good profit margin and that we only scratched market surface, I could have proposed someone to manage the business outside of R&D and continue the project. We were, however, small and were more interested in technology than profit then.

Sunday, January 13, 2013

Polychrome International Today Vol. 1 no. 2 June 1979

Old familiar faces from Europe in this issue of Polychrome International, click HERE to read all four pages.

Wednesday, January 9, 2013

Annual report 1974

Here is the Annual report 1974, to read the entire contents click HERE.

A lot of international flavor, we were expanding internationally.

Monday, January 7, 2013

Early days of Clark R&D

Start up of Clark film production was a disaster in retrospect. It brew up when DIC tried to market the Clark produced film in Japan. Upset by the outcome DIC decided to send R&D personnel to Clark to help improve the quality. I was asked to be the interim/temporary research director till a new permanent director was found. Joe Piot probably thought I would be a good care taker of Japanese contingent. I also had the advantage of having a degree in photographic science and having worked for the oldest (and smallest ) photographic company in Japan so that I was familiar with the photographic emulsion. I found out quickly that the technology we had was a DuPont type random grain silver halide emulsion and that the market was moving quickly to Kodak and Fuji type cubic crystal emulsion. Gene Wilkerson who came form DuPont and till then led the group was a brilliant eccentric and was focused his eyes to up and coming Daylight Handling Film and auto positive film both of which commanded higher profit margin than ordinary litho film. He eventually developed both product successfully. But the development of cubic crystal was done by Jon da Silva, another eccentric chemist from Brazil, and his devoted and capable assistant Penny Mullen. DIC invested heavily in manpower and the several chemists stationed in Clark together with their visiting consultant from Japan worked hard to develop cubic crystal emulsion of their own. After a couple years of parallel development we set a deadline date to review both approaches and all agreed that the unconventional approach Jon da Silva came up with produced better results with more stability. Both Rapid Access film and regular litho film were made using this cubic crystal and revamped the entire Clark product line while during the three years I was involved. Since Gene was nocturnal and I was a part time director, daily chore of keeping everyone busy and productive fell on the shoulder of capable John Pilot, who with his quiet demeanor and in depth knowledge of technology was highly regarded and respected by everyone. Steve Gallo played an important role as the bridge person between R&D and production. Since we did not have a pilot coater, he had to manage and keep a good relationship to fit our production trial done well and on time. Although not part of R&D, Victor Tkaczenko was a key player in new product development. His technical service department served as in house customer or a quick and also often an in depth evaluation of freshly produced products.

Thursday, January 3, 2013

Polyworld Spring of '85 vol. 5 no.1

The entire content is HERE

Subscribe to:

Posts (Atom)